Case Study

Posted on

Australia’s aviation sector accounts for around 5% of Australia’s carbon dioxide emissions. Through important industry-focused research, dreams of powering the aviation industry towards net zero are closer to reality.

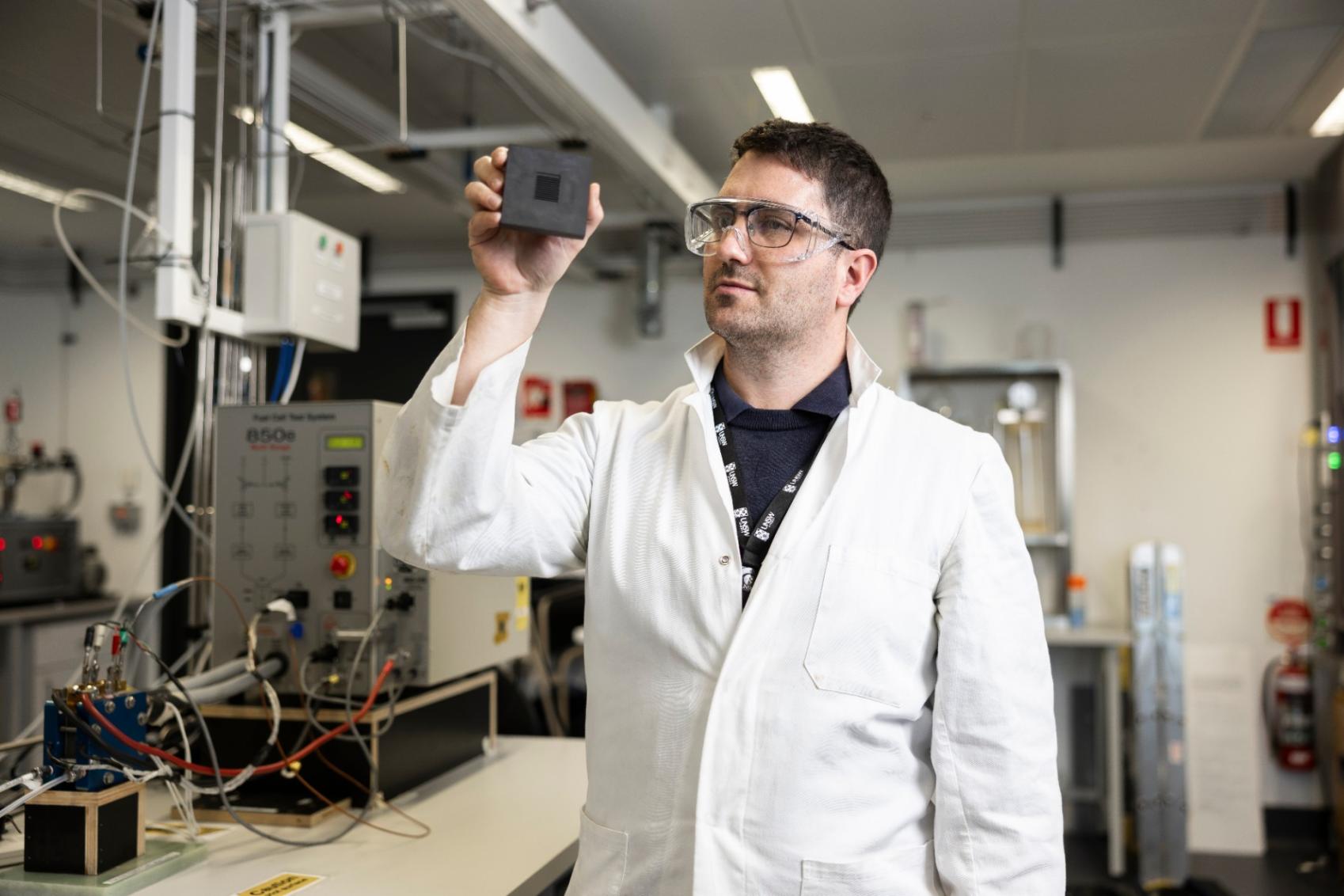

Supported by an Australia’s Economic Accelerator (AEA) Seed grant, researchers Dr Quentin Meyer and Professor Chuan Zhao at UNSW Sydney’s School of Chemistry are developing a prototype of high-temperature fuel cells using low-cost catalysts.

The project’s goal is to produce fuel cells to power small drones and assist the aviation transport sector in developing clean aircraft that are low-cost, low-weight and high range.

While the industry considers improvements to engines and sustainable biofuels to reduce carbon emissions, the potential for hydrogen-powered aircraft was first demonstrated through various prototypes as early as the 1950s.

By focusing their research on hydrogen fuel cells, Lead Entrepreneur and Lead Chief Investigator Dr Meyer and Collaborating Entrepreneur Professor Zhao are working to overcome some of the significant challenges with hydrogen-powered aircraft.

One of the challenges is to develop a fuel cell that is light enough for the aircraft to carry.

“In the aviation industry, you want something as light as possible for take-off, taxi and landing,” Dr Meyer says.

“The battery needed to power a truck, for example, accounts for about 30% of its weight – so just imagine the size of the battery needed for a plane flying from Australia to Europe.”

Another challenge faced by fuel cells has been device integration.

“Often, a fuel cell system is made first and then it needs to be redesigned so it can be used in a device,” Dr Meyer says.

“This is a costly and somewhat inefficient approach. But we’ll identify the drone we want at the beginning of the project and then design the fuel cell system around it.

“This approach must remain the same for scaling up to larger aircraft one day – finding the aircraft first, then designing the fuel cell and system around it.”

Their aim is to power drones with hydrogen fuel cells within the year. The next step beyond the project is scaling this up to larger aircraft.

Dr Meyer says using hydrogen is not only good for the environment, but also has tremendous commercial potential, with Airbus planning to launch its first commercial hydrogen-powered aircraft by 2035 and companies turning their sights towards high temperature fuel cells as a lighter solution.

The Australian Government recently released the 2024 National Hydrogen Strategy, which aims for a clean, innovative, safe and competitive hydrogen industry that benefits all Australians, positioning us as a major global player by 2030.

With that aim in sight, technological improvements for electrolysers – which split water into hydrogen and oxygen using electricity – are already lowering costs and increasing production potential.

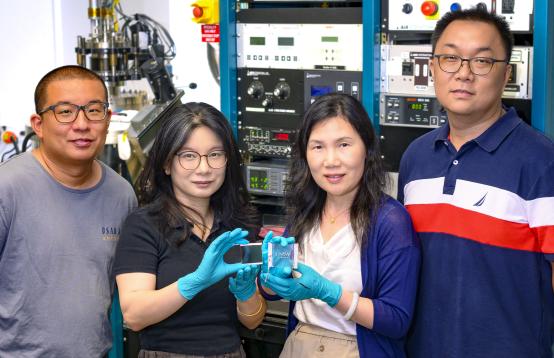

Fortunately, Professor Zhao is a world-leading expert in developing low-cost catalysts for water electrolysers and fuel cells.

“We have already created some of the most efficient catalysts for water splitting,” Professor Zhao said.

Creating these high-performance catalysts is a game-changer for the hydrogen economy.

“Fuel cells previously used large amounts of platinum, which is both very rare and very expensive,” Professor Zhao says.

“Our fuel cells team, led by Dr Meyer, had several breakthroughs in platinum-free catalysts, which has given us unique tools to develop the next generation of low-cost materials.

“We are working towards demonstrating our catalysts in high-temperature fuel cells and are designing the fuel cell system at the same time, with a prototype expected by February or March 2025, and then its device integration.”

The continued research, investment and collaboration between industry stakeholders and governments is essential to overcoming the challenges on the road to making hydrogen aviation a reality.

Dr Meyer and Prof Zhao are excited by the potential of their research, which is driving the next disruptive evolution in the field.

It’s another example of how the AEA is supporting the Australian Government’s Future Made in Australia policy and enabling Australia’s leading entrepreneurial researchers to transform world-class research into the new industries, services and jobs of tomorrow.

AEA is a $1.6 billion Australian Government investment aimed at transforming Australia’s research translation and commercialisation landscape.